Our fastening systems are compliant with international and local standards, including AS 5216 / SA TS 101, and offer a wide range of solutions for various base materials.

They can also be used for non-structural and structural elements in designs requiring seismic and / or fire approvals.

We also offer back up engineering services to help with design, design software, onsite testing and consultation, training, technical data and documentation.

Our anchor systems are all designed to make your design safer and more reliable:

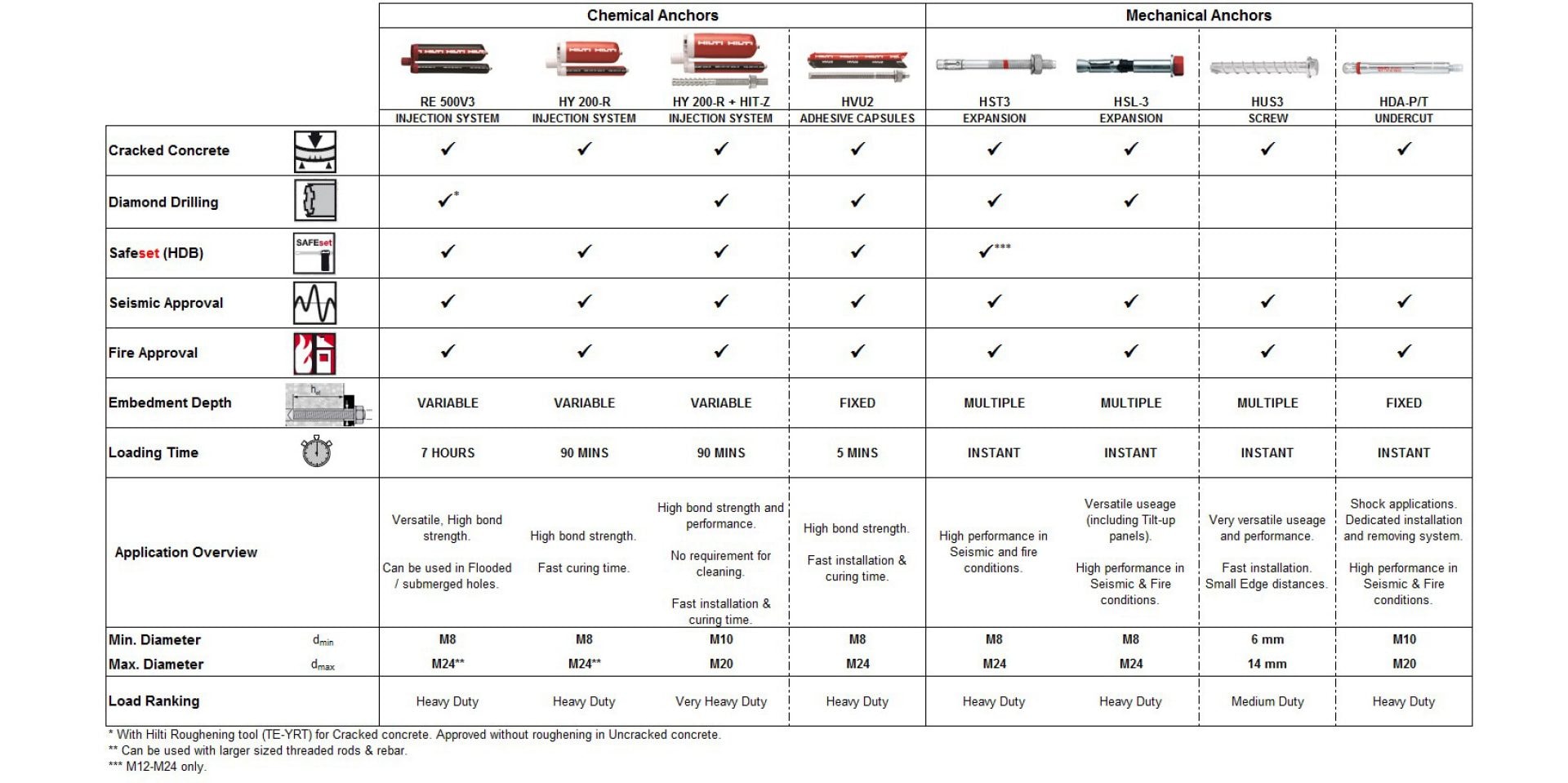

- Hilti HVU2 Capsule System – designed for highest performance, including use in diamond cored holes, seismic conditions and fire resistances. Fast installation and curing time.

- Hilti HIT-HY 200 + HIT-Z SafeSet Technology – highest bond strengths due to a combination of adhesion properties of HY 200-R and helical design of HIT-Z rods, leading to the elimination for any need for manual cleaning of the drilled holes.

- Hilti HIT-RE 500 V3 + HIT-V – Multitude of applications in various base materials under different installation and environmental conditions.

- Hilti HIT-HY 200-R + HIT-V – High strength, fast curing, chemical anchor for use in concrete.

- Hilti HST3 Expansion Anchors – intricately designed for optimum performance. Carries various approvals and performance in severe conditions.

- Hilti HIT-HY 270 Chemical Adhesive – use for masonry applications and with our Hilti PROFIS Engineering design software, based on state of the art testing and design methodology to achieve the highest level of safety in your design.